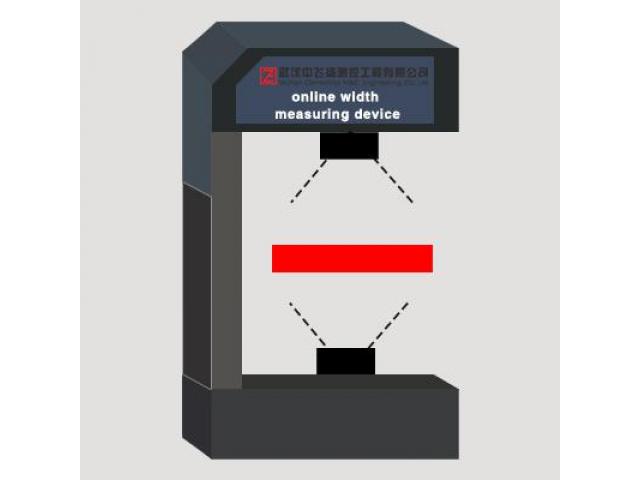

WGS-L020 Flat Steel/Ribbon Iron Width Measuring System

5000.00 Dollar US$

Published date: October 14, 2022

- Location: Wuhan, Doha, Ad Dawhah, Qatar

WGS-L020 Flat Steel/Ribbon Iron Width Measuring System

Overview

Whether the width and thickness of the flat steel/ribbon iron width measurement device can meet the standard in the production process directly determines the quality of the flat steel/ribbon iron. How to carry out high-precision measurement of flat steel produced at high speed is the key technology to improve the production efficiency and quality of flat steel. The flat steel/ribbon iron high-speed width measuring system developed by our company can monitor the whole process of flat steel production in real time. It can be used for the on-line analysis, processing, display and function alarm for the detected parameters of the width and thickness. We can provide customers with professional solutions.

The measuring principle of the system

The device adopts industrial laser sensor, through the principle of laser triangulation reflection: the laser beam is amplified to form a laser line and projected onto the surface of the object to be measured, the reflected light passes through the high-quality optical system to be projected onto the imaging matrix. Then the distance (Z axis) from the sensor to the measured surface and position information (X axis) along the laser line can be got after calculating. By moving the measured object or sensor, a set of three-dimensional measured value can be obtained. When measuring, we need to install a laser measurement sensor device directly above and below the ribbon iron. When the ribbon iron passes through, the width distance from the left and right of the ribbon iron and the height distance from the sensor to the ribbon iron can be measured by laser scanning. The thickness of flat steel can be measured by two sensors up and down.

The flat steel width measuring system is mainly composed of line laser measurement sensors, connectors, front-end data acquisition, operation station (workstation) and server, mechanical structure, cooling protection device, etc. These devices form an independent measurement and calculation network, and through the high-speed data measurement and calculation of the system to achieve the alarm control of the detection record.

The features of the system

It can effectively identify and compensate the beating, inclination, side deviation and profile of the flat steel/ribbon iron to be tested;

Moving image linear noise correction technology, 3D modeling technology;

The software has self-diagnosis function;

Full digital detection, automatic calibration system;

Unique optical vibration compensation technology;

High measurement accuracy and fast response;

Using optical fiber signal transmission;

Quality control alarm;

Excellent mathematical model realizes accurate width detection of the bad profile;

The software interface is good, powerful, easy to operate and maintenance-free;

The technical parameters

Measuring distance: less than 300m (according to the on-site environment)

Resolution: ±0.05mm

Repeatability: 0.1mm

Measurement frequency: 80KHz

Measurement output frequency: 50Hz (adjustable)

Laser class: 2 (IEC60825-1:2014)

Protection class: IP65

Communication: TCP/IP communication

Measurement range of temperature: 0℃-2000℃

Working temperature: -20℃-60℃

Overview

Whether the width and thickness of the flat steel/ribbon iron width measurement device can meet the standard in the production process directly determines the quality of the flat steel/ribbon iron. How to carry out high-precision measurement of flat steel produced at high speed is the key technology to improve the production efficiency and quality of flat steel. The flat steel/ribbon iron high-speed width measuring system developed by our company can monitor the whole process of flat steel production in real time. It can be used for the on-line analysis, processing, display and function alarm for the detected parameters of the width and thickness. We can provide customers with professional solutions.

The measuring principle of the system

The device adopts industrial laser sensor, through the principle of laser triangulation reflection: the laser beam is amplified to form a laser line and projected onto the surface of the object to be measured, the reflected light passes through the high-quality optical system to be projected onto the imaging matrix. Then the distance (Z axis) from the sensor to the measured surface and position information (X axis) along the laser line can be got after calculating. By moving the measured object or sensor, a set of three-dimensional measured value can be obtained. When measuring, we need to install a laser measurement sensor device directly above and below the ribbon iron. When the ribbon iron passes through, the width distance from the left and right of the ribbon iron and the height distance from the sensor to the ribbon iron can be measured by laser scanning. The thickness of flat steel can be measured by two sensors up and down.

The flat steel width measuring system is mainly composed of line laser measurement sensors, connectors, front-end data acquisition, operation station (workstation) and server, mechanical structure, cooling protection device, etc. These devices form an independent measurement and calculation network, and through the high-speed data measurement and calculation of the system to achieve the alarm control of the detection record.

The features of the system

It can effectively identify and compensate the beating, inclination, side deviation and profile of the flat steel/ribbon iron to be tested;

Moving image linear noise correction technology, 3D modeling technology;

The software has self-diagnosis function;

Full digital detection, automatic calibration system;

Unique optical vibration compensation technology;

High measurement accuracy and fast response;

Using optical fiber signal transmission;

Quality control alarm;

Excellent mathematical model realizes accurate width detection of the bad profile;

The software interface is good, powerful, easy to operate and maintenance-free;

The technical parameters

Measuring distance: less than 300m (according to the on-site environment)

Resolution: ±0.05mm

Repeatability: 0.1mm

Measurement frequency: 80KHz

Measurement output frequency: 50Hz (adjustable)

Laser class: 2 (IEC60825-1:2014)

Protection class: IP65

Communication: TCP/IP communication

Measurement range of temperature: 0℃-2000℃

Working temperature: -20℃-60℃

Related listings

-

LAG-S400 Infrared Converter Slag Detection System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022LAG-S400 Infrared Converter Slag Detection System Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in th...

LAG-S400 Infrared Converter Slag Detection System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022LAG-S400 Infrared Converter Slag Detection System Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in th... -

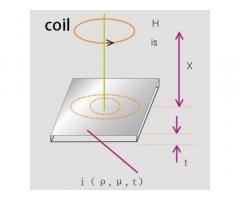

MLC-V235 Continuous Casting Mold Level Automatic Measurement System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022MLC-V235 Continuous Casting Mold Level Automatic Measurement System Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intens...

MLC-V235 Continuous Casting Mold Level Automatic Measurement System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022MLC-V235 Continuous Casting Mold Level Automatic Measurement System Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intens... -

MAC-G350 Automatic Mold Flux Feeding Machine5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022MAC-G350 Automatic Mold Flux Feeding Machine Overview The MAC-G350 automatic mold flux feeding system is a mold flux feeding equipment that adopts the method of pneumatic transmission flux feeding. This method can place the charging bin in a centrali...

MAC-G350 Automatic Mold Flux Feeding Machine5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 14, 2022MAC-G350 Automatic Mold Flux Feeding Machine Overview The MAC-G350 automatic mold flux feeding system is a mold flux feeding equipment that adopts the method of pneumatic transmission flux feeding. This method can place the charging bin in a centrali...