MAC-G350 Automatic Mold Flux Feeding Machine

5000.00 Dollar US$

Published date: October 14, 2022

- Location: Wuhan, Doha, Ad Dawhah, Qatar

MAC-G350 Automatic Mold Flux Feeding Machine

Overview

The MAC-G350 automatic mold flux feeding system is a mold flux feeding equipment that adopts the method of pneumatic transmission flux feeding. This method can place the charging bin in a centralized manner and can carry out charging operation simultaneously for one machine and many continuously cast products. It is convenient and stable to use. According to different steel grades, casting speed, vibration and other process parameters, the system can analyze and calculate the accurate mold powder addition amount through intelligent software. Then the system sends out signals to control the mold powder addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux and realizes the automation of mold flux addition.

The technical parameters

1. Mold width of continuous casting machine: width 100mm~2000mm

2. Mold thickness of continuous casting: thickness 50mm/500mm

3. Working casting speed range of continuous casting machine: 0.1m/min~2.7m/min

4. Power conditions: 220V/50Hz;

5. Feeding translation speed: 0-100mm/s

6. Traverse stroke of single mold flux nozzle: 300-700mm

7. mold flux feeding rate: 0.25~2.0 l/min

8. Storage bin volume: single 1m3

9. Transmission method: pneumatic conveying

10. Delivery gas: nitrogen

11. Storage bin heating range: 0-150 degrees Celsius

12. Storage bin stirring method: motor stirring

13. Installation method: fixed storage bin, mobile feeding machine

14. Control mode: local/remote control, automatic/manual mode

15. Speed interlock control mode: 4-20mA

16. Control technology: robotic arm motion control technology

Overview

The MAC-G350 automatic mold flux feeding system is a mold flux feeding equipment that adopts the method of pneumatic transmission flux feeding. This method can place the charging bin in a centralized manner and can carry out charging operation simultaneously for one machine and many continuously cast products. It is convenient and stable to use. According to different steel grades, casting speed, vibration and other process parameters, the system can analyze and calculate the accurate mold powder addition amount through intelligent software. Then the system sends out signals to control the mold powder addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux and realizes the automation of mold flux addition.

The technical parameters

1. Mold width of continuous casting machine: width 100mm~2000mm

2. Mold thickness of continuous casting: thickness 50mm/500mm

3. Working casting speed range of continuous casting machine: 0.1m/min~2.7m/min

4. Power conditions: 220V/50Hz;

5. Feeding translation speed: 0-100mm/s

6. Traverse stroke of single mold flux nozzle: 300-700mm

7. mold flux feeding rate: 0.25~2.0 l/min

8. Storage bin volume: single 1m3

9. Transmission method: pneumatic conveying

10. Delivery gas: nitrogen

11. Storage bin heating range: 0-150 degrees Celsius

12. Storage bin stirring method: motor stirring

13. Installation method: fixed storage bin, mobile feeding machine

14. Control mode: local/remote control, automatic/manual mode

15. Speed interlock control mode: 4-20mA

16. Control technology: robotic arm motion control technology

Related listings

-

MOC-K100 Mould Online Oscillation Monitoring System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022MOC-K100 Mould Online Oscillation Monitoring System Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly coo...

MOC-K100 Mould Online Oscillation Monitoring System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022MOC-K100 Mould Online Oscillation Monitoring System Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly coo... -

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc...

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc... -

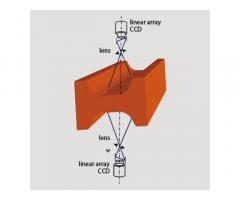

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of ho...

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of ho...