MOC-K100 Mould Online Oscillation Monitoring System

5000.00 Dollar US$

Published date: October 13, 2022

- Location: Wuhan, Doha, Ad Dawhah, Qatar

MOC-K100 Mould Online Oscillation Monitoring System

Overview

Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area.

The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process.

MOC-K100 mould online oscillation monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel.

The meaning of the system

1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality.

2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance.

3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair.

4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident.

5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product.

6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed.

The parameters of the system

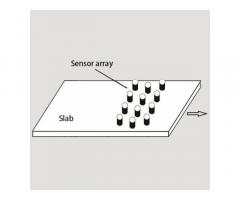

1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged

2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes)

3. Sensitivity: 1000mV/g

4. Frequency range: 0.04~10HZ

5. Frequency accuracy: ±0.01 Hz

6. Amplitude accuracy: 0.005mm

7. Transmission mode: wired digital transmission; wireless transmission

8. Host: 3U standard rack; handheld device

9. Sensor power supply: 24V.DC

10. Host power supply: 220V.AC/50Hz

The structure of the system

The main components of the continuous casting mould online oscillation detection system are:

1. Three-dimensional oscillation measurement sensor

2. Handheld oscillation sensor calibrator

3. Dedicated signal connection cable

4. Preamplifier

5. Operation processing unit

6. Graphic display terminal

7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components

8. Control cabinet

Overview

Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area.

The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process.

MOC-K100 mould online oscillation monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel.

The meaning of the system

1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality.

2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance.

3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair.

4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident.

5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product.

6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed.

The parameters of the system

1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged

2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes)

3. Sensitivity: 1000mV/g

4. Frequency range: 0.04~10HZ

5. Frequency accuracy: ±0.01 Hz

6. Amplitude accuracy: 0.005mm

7. Transmission mode: wired digital transmission; wireless transmission

8. Host: 3U standard rack; handheld device

9. Sensor power supply: 24V.DC

10. Host power supply: 220V.AC/50Hz

The structure of the system

The main components of the continuous casting mould online oscillation detection system are:

1. Three-dimensional oscillation measurement sensor

2. Handheld oscillation sensor calibrator

3. Dedicated signal connection cable

4. Preamplifier

5. Operation processing unit

6. Graphic display terminal

7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components

8. Control cabinet

Related listings

-

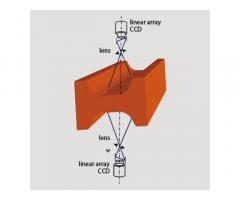

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc...

ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc... -

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of ho...

ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD)5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of ho... -

Infrared/Laser Cut-to-Length Cutting System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022Infrared/Laser Cut-to-Length Cutting System Overview The all-digital non-contact infrared automatic cut-to-length cutting system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digit...

Infrared/Laser Cut-to-Length Cutting System5000.00 Dollar US$Other Services Doha (Ad Dawhah) October 13, 2022Infrared/Laser Cut-to-Length Cutting System Overview The all-digital non-contact infrared automatic cut-to-length cutting system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digit...